Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

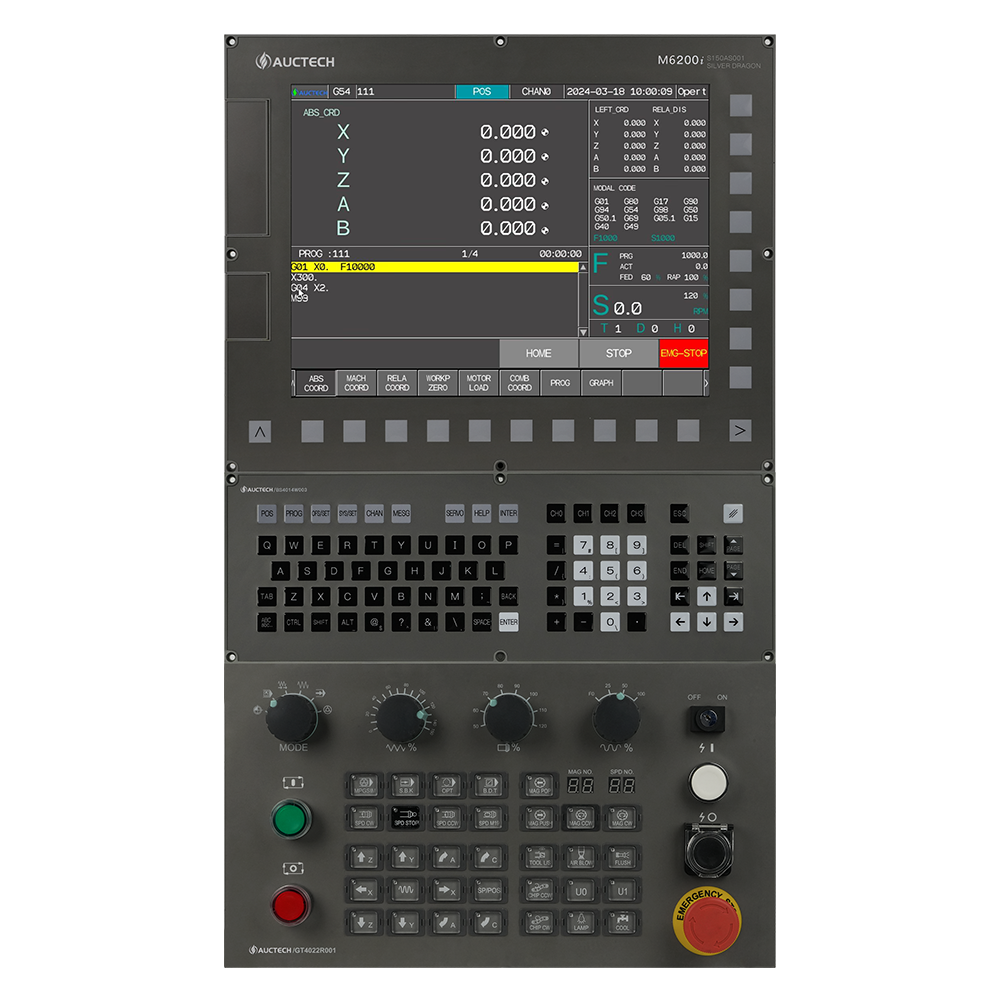

M618i Engraving and Milling Machine

The M618i Engraving and Milling Machine, powered by Auctech's advanced M618i/M6180i CNC Controller, epitomizes precision, efficiency, and versatility in CNC machining. Designed to meet the demanding requirements of modern manufacturing, this machine offers unparalleled performance for a wide range of engraving and milling applications.

- Product Details

-

Download

Product Description

The M618i Engraving and Milling Machine is engineered with cutting-edge technology and precision craftsmanship, delivering superior results with every operation. At its core lies the Auctech M618i/M6180i CNC Controller, built on ARM architecture and equipped with industry-standard 3-axis engraving and milling capabilities.

Product Specification

|

Screen size |

10.4 |

|

MIll bus |

√ |

|

Ether CAT |

√ |

|

Bus/Pulse/Analog |

√ |

|

Basic controlled axes |

4 |

|

Max controlled axes |

50 |

|

Max interpolated axes |

3 |

|

Max principal axes |

2 |

|

Channels |

2 |

|

Basic l/O points |

32+24 |

|

Max I/O points |

128+96 |

|

Multi-PLC |

|

|

Dual-drive |

√ |

|

Hardware current |

√ |

|

RTCP control |

|

|

GSG |

√ |

|

NIA |

√ |

|

Full closed-loop control |

√ |

|

Proaramming |

√ |

|

INTERNET |

|

|

Remote debugging |

|

|

Standard panel |

|

|

GS3022W001 |

|

|

GH4012W001 |

|

|

GH4025L001 |

|

|

|

Product Features and Advantages

1. Advanced CNC Controller: The Auctech M618i/M6180i CNC Controller, based on ARM architecture, provides the backbone for precise and efficient machining operations.

2. High-Speed and High-Precision Functions: The GSG and NIA functions deliver exceptional performance, particularly suited for high-gloss processing with small tools, ensuring impeccable results every time.

3. Versatile Protocol Support: With support for both MIII and EtherCAT protocols, the machine offers seamless connectivity and integration into diverse manufacturing setups.

4. Flexible Configuration Options: Equipped with support for bus spindle, pulse, and DA spindle control, the machine allows for versatile configuration to accommodate various machining requirements.

5. Built-in Tapping Debugging Interface: The integrated tapping debugging interface enables users to optimize machine performance and achieve high-speed rigid tapping with precision and reliability.

Benefits

Training and Support: AUCTECH provides comprehensive training and support to help clients maximize the value of their automation investments. From initial setup and configuration to ongoing maintenance and troubleshooting, AUCTECH's team of experts is available to assist clients every step of the way, ensuring smooth operation and optimal performance.

Industry Expertise: With a long-standing commitment to the field of intelligent manufacturing, AUCTECH brings a wealth of industry expertise to the table. Clients benefit from the company's deep understanding of various sectors, including auto parts, electronics, medical, packaging, and more, ensuring that their automation solutions are tailored to meet industry-specific challenges and requirements.

Download

-

Auctech M6 Series CNC Brochure _V2.0 (20240202).pdf