Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

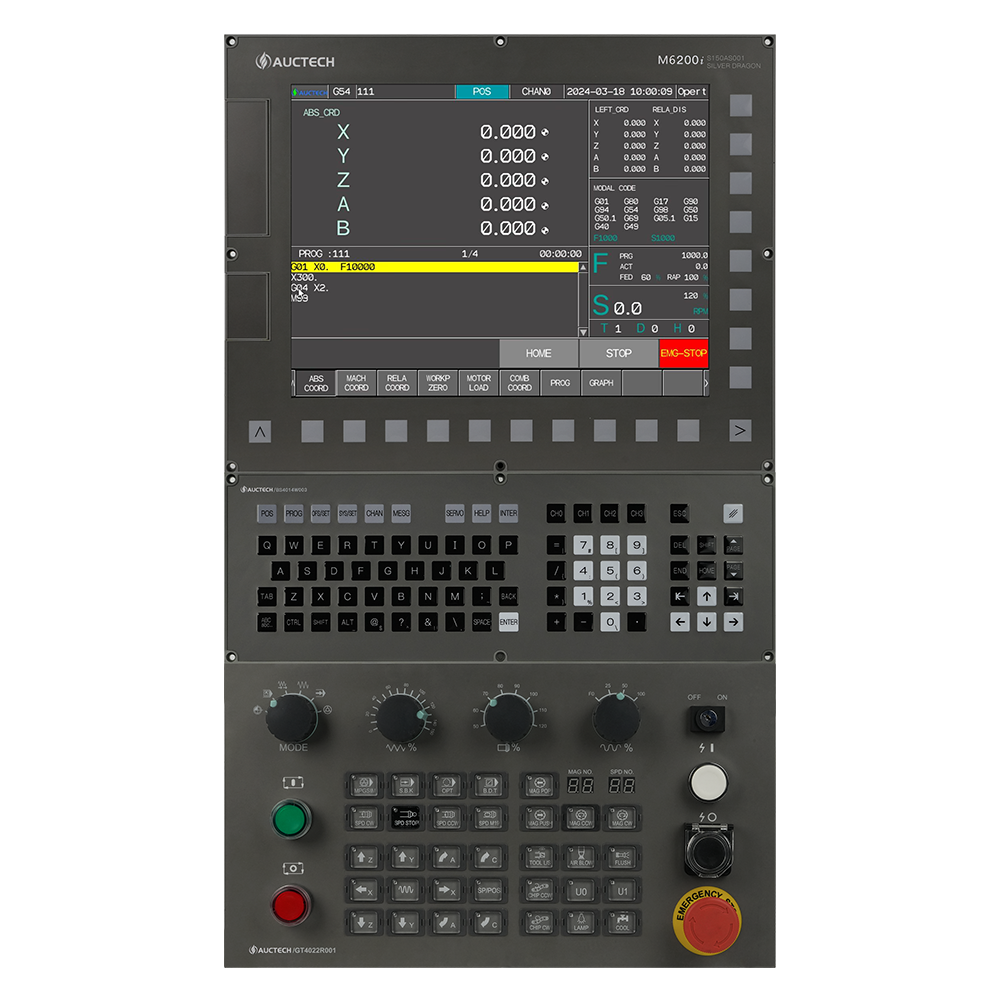

M6180i Engraving and Milling Machine

The M6180i Engraving and Milling Machine represents a cutting-edge advancement in CNC controller technology, designed to meet the demands of precision machining and engraving tasks across various industries. Powered by a combination of innovative hardware and software features, this machine ensures exceptional performance, reliability, and flexibility in operation.

- Product Details

-

Download

Product Description

The M6180i Engraving and Milling Machine integrates state-of-the-art components and technologies to deliver unparalleled precision and efficiency in machining operations. Its foundation lies in the ARM A9 framework, renowned for its low power consumption and high performance capabilities. Moreover, the inclusion of the Nanometer-scale Interpolation Algorithm (NIA) enhances the machine's ability to achieve intricate detailing with utmost precision.

Product Specification

|

Screen size |

10.4 |

|

MIll bus |

√ |

|

Ether CAT |

√ |

|

Bus/Pulse/Analog |

√ |

|

Basic controlled axes |

3 |

|

Max controlled axes |

50 |

|

Max interpolated axes |

3 |

|

Max principal axes |

2 |

|

Channels |

2 |

|

Basic l/O points |

32+24 |

|

Max I/O points |

128+96 |

|

Multi-PLC |

|

|

Dual-drive |

√ |

|

Hardware current |

√ |

|

RTCP control |

|

|

GSG |

√ |

|

NIA |

√ |

|

Full closed-loop control |

√ |

|

Proaramming |

√ |

|

INTERNET |

|

|

Remote debugging |

|

|

Standard panel |

|

|

GS3022W001 |

|

|

GH4012W001 |

|

|

GH4025L001 |

|

|

|

Product Features and Advantages

1. High-Speed Performance: Equipped with the latest ARM A9 framework, the machine combines high performance with energy efficiency, enabling swift and precise machining operations.

2. Advanced Interpolation: The Nanometer-scale Interpolation Algorithm (NIA) ensures smooth and accurate motion control, allowing for the creation of intricate designs and fine detailing with precision.

3. Gantry Application: The dual-drive synchronous gantry application facilitates stable and synchronized movement, ensuring uniformity in machining across the workpiece.

4. Precision Control: The high-speed and high-precision slope conversion GSG feature enhances control over machining processes, guaranteeing superior surface finish and dimensional accuracy.

5. Versatile Compatibility: With its open CNC interface, the machine supports various servo systems, including MIIl/EtherCAT/pulse/simulation, providing compatibility with both domestic and foreign systems.

6. Unified Bus Configuration: The integration of Bus I/O with the RJ45 interface simplifies the design and wiring process, enabling seamless connectivity between servo modules, I/O units, and external auxiliary components.

7. Convenient Editing: PLC online editing functionality allows for easy customization and enhancement of machine functions, streamlining the workflow and facilitating prompt adjustments.

8. Enhanced Storage Options: Dual USB expandable storage ensures ample space for data storage and retrieval, enabling efficient management of machining programs and settings.

9. Online Optimization: Built-in servo adjustment, circular adjustment, and high-speed tapping functions empower users to optimize machining processes in real-time, enhancing productivity and efficiency.

10. Macro Programming: The open macro program function offers flexibility in programming, allowing users to create custom routines tailored to specific machining requirements.

Download

-

Auctech M6 Series CNC Brochure _V2.0 (20240202).pdf